Discover The Most Innovative Way To Increase Your Production Capacity: Tezmaksan Cubebox And Brother Speedio Cooperation

The partnership between CubeBOX and Brother Speedio is set to revolutionize your production line, maximizing performance. Tim Whitehouse, Managing Director of Whitehouse Machine Tools, shared how valve manufacturer Ross Pneumatrol increased its production output by up to 50% thanks to the collaboration between Tezmaksan’s CubeBOX and Brother Speedio.

Ross Pneumatrol supplies actuators, pneumatic, and electro-pneumatic valves, among other products, to various industries. Since 2019, the company has doubled its turnover to €7 million due to growth, with exports now accounting for over 60% of revenue, driven by strong demand in the oil and gas sector and better-than-expected sales in Asia.

Investment for Growth

To meet rising demand, Ross Pneumatrol invested in three Brother 30-taper high-efficiency machining centers, each with dual-pallet changing capabilities. Supplied by Whitehouse Machine Tools, these new machines were designed to meet the increased demand for prismatic machined components like valve bodies and pilot end covers. Installed in September 2022, the first cell in the aluminum machining section featured a Brother Speedio S700X2 VMC equipped with a Feedio robotic system for component transport using a camera vision system.

Automation Expertise Makes a Difference

A camera vision system enabled the robot to detect how a part was placed on the upper conveyor, sending it to an exit conveyor post-machining. Ross Pneumatrol’s Operations Manager, Tommy Cooney, emphasized their decision to continue working with Whitehouse Machine Tools, a partnership spanning over 20 years, citing their engineering expertise and support services as invaluable.

CubeBOX Boosts Productivity

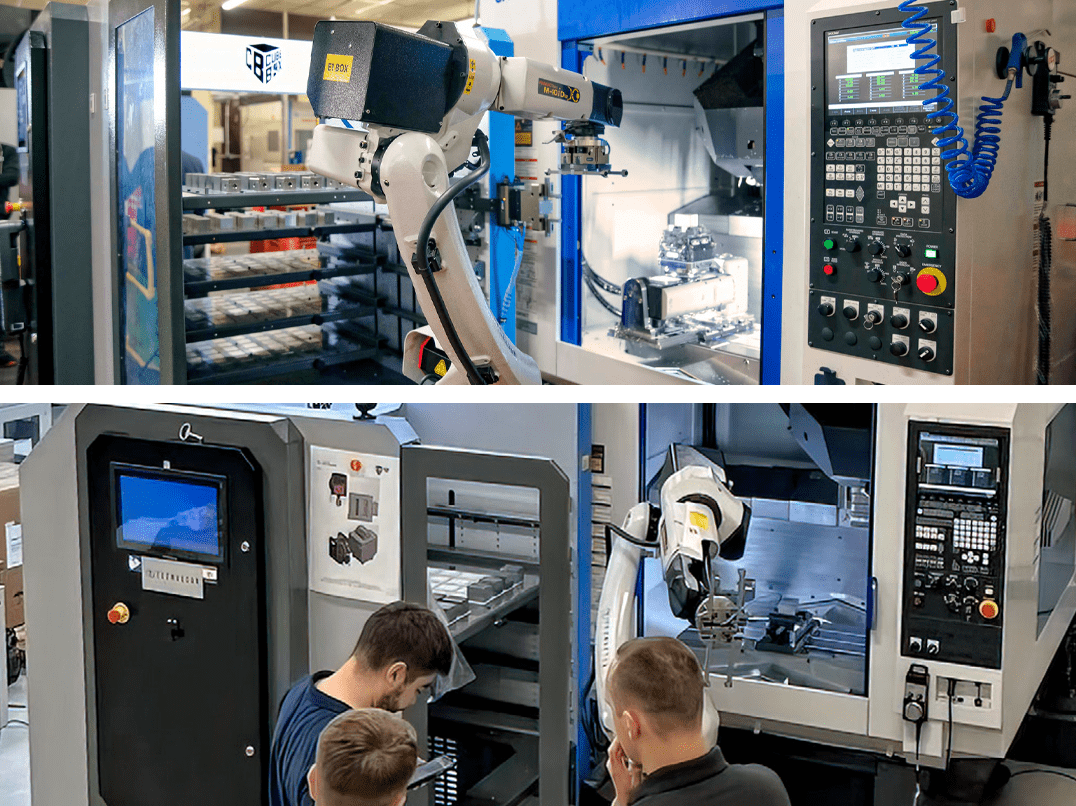

Instead of opting for another Feedio unit, Ross Pneumatrol invested in Tezmaksan’s CubeBOX automation system on the recommendation of Whitehouse Machine Tools, Tezmaksan’s UK distributor. CubeBOX offers seamless automation by directly processing parts, eliminating the need for costly pallet changes. Cooney explained that with this investment, they could operate the Brother machines unattended during the night shift.

Shorter Cycle Times

Cooney noted that cycle times on the two latest Brother machines were 40% shorter than their older 30- and 40-taper machines, with aluminum parts taking 7 to 10 minutes and stainless steel versions 15 to 18 minutes to complete.

Ross Pneumatrol valued the engineering support provided by Whitehouse Machine Tools, which included time studies, application engineering, and CAD software-based programming strategies.

Tezmaksan’s CubeBOX system, installed at Ross Pneumatrol, featured a Fanuc M10ID12 industrial robot with a 12 kg capacity and five drawers for part storage. It was delivered as a plug-and-play solution without requiring prior robot programming knowledge, compatible with one or two CNC machines of any brand.

This partnership highlights how automation and innovation, through solutions like CubeBOX and Brother Speedio, can significantly enhance production capabilities.

24.10.2024

24.10.2024