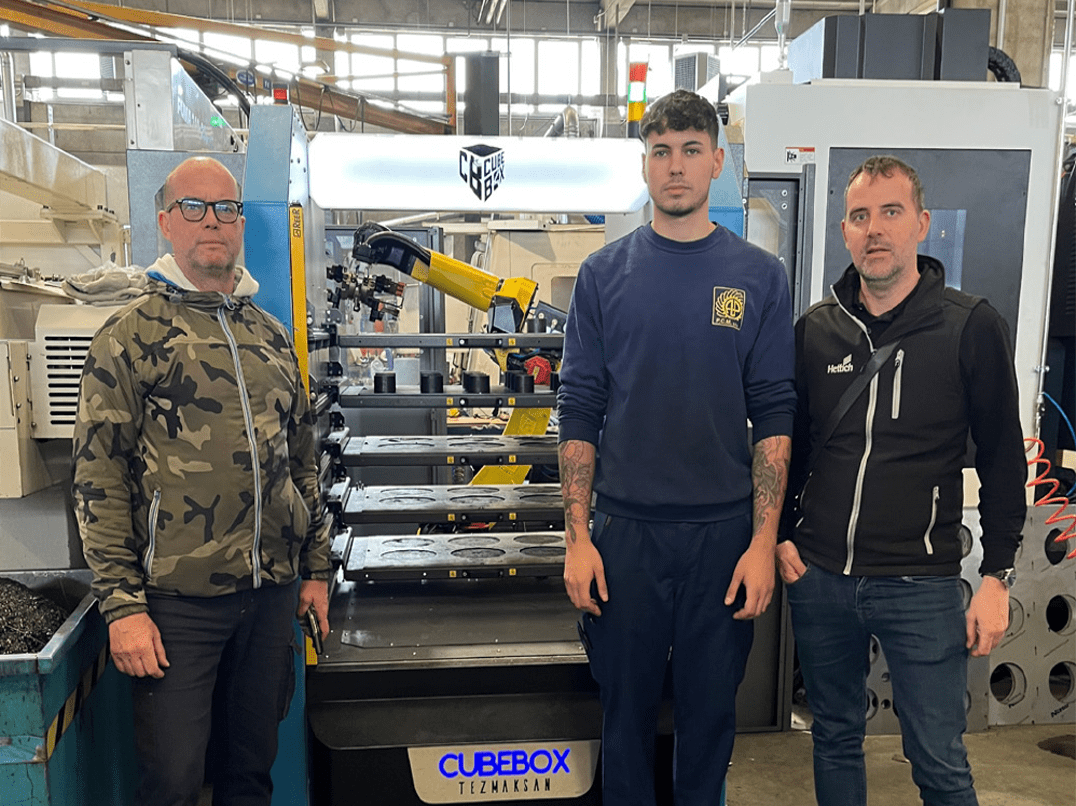

Pcm: CubeBOX Has Taken Production To The Next Level By Feeding Three Lathes At The Same Time!”

The Italian-based PCM company uses innovative technologies to keep quality and efficiency at the highest level in production. The company, which recently optimized its production line by choosing Tezmaksan's CubeBOX DR model, explained how the flexible software and high feeding capacity offered by this technology make their jobs easier.

Can we recognize PCM?

As PCM, we produce gear wheels. The competition in the industry is very intense. We are constantly using innovative technologies to keep quality and efficiency at the highest level in our production process. In this direction, we have recently started using the CubeBOX DR model. Thanks to the CubeBOX, it allows it to feed 3 machines at the same time; thus, our production process becomes more efficient and uninterrupted. CubeBOX DR has increased the automation level of our production line and provided a more flexible and efficient working environment.

You have chosen the CubeBOX DR model to feed your production line. Can you tell us about the process?

We have been looking for a robotic solution for some time to make our production line more efficient and reduce the workload. The contribution of Tezmaksan dealer Vimacchine to us in this regard is very great. We started to study the CubeBOX DR model they proposed and we believed that it would meet our needs and decided on this model. It was an amazing experience for us that the robot could feed 3 machines at the same time, especially two lathes and an upright machining center.

You have experienced CUBEBOX, can you pass on your observations?

I can list the advantages. First of all, our workload has decreased significantly. Thanks to the automation system, we can now perform many of the tasks we used to do more quickly and error-free. This saves us a lot of time and cost. In particular, the increase in our production efficiency manifests itself at every stage of our business. Now we can produce more products in a shorter time, which makes it possible for us to provide fast service to our customers. Thanks to the flexible software of CUBEBOX, the management of our production line has become much easier. The ability of the robot to feed 3 machines at once and the flexibility offered by the software stood out as the most important advantages of this model. The support of the Tezmaksan team was also very valuable during this process. They were there for us in all our questions and needs. We have full confidence in Tezmaksan and CUBEBOX now!

You said software flexibility... Can you give some more details?

Thanks to its user-friendly interface and flexible programming options, we can quickly adapt to different production scenarios. We can easily make the changes we need while optimizing our production processes. With the software flexibility supporting our capacity, we have had the opportunity to direct our workforce to more strategic jobs. This saves both time and minimizes possible errors. In short, I can say that ”this solution offered by Tezmaksan has taken our production line to the next level".

24.10.2024

24.10.2024