We Increased Our Productıon Minimum 15 Percent

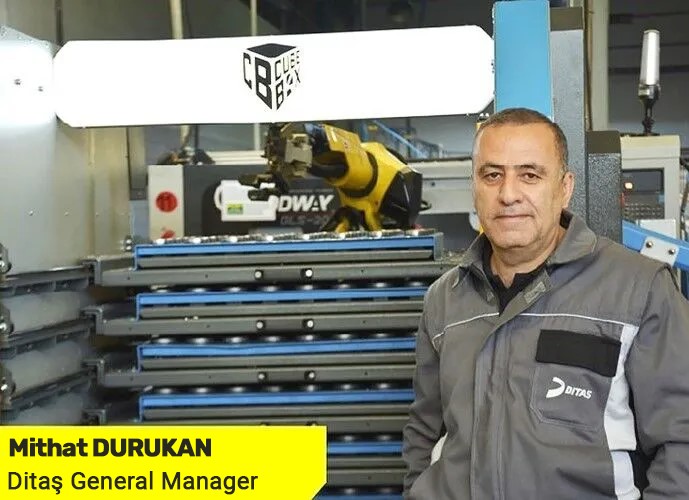

Ditaş Doğan Spare Parts Manufacturing and Technical Inc. Maintenance and Repair Manager Mithat Durukan said that they increased their production volume by 15 percent thanks to Tezmaksan’s domestic and national robotic automation system Cubebox.

Mithat Durukan answered the questions we wondered about the Cubebox system, which can be used in harmony with CNC machines thanks to its standard design:

Dogan Spare PartsManufacturing and Technical Inc. was established in 1972 with the aim of producing tie rod end, ball joint, tie rod, swing arm, drawbar, stabilizer, vehicle infrastructure parts such as arm and V drawbar and after becoming operational in 1978 today, an annual production of 7 million 800 thousand units rod producing for Turkey’s largest OE with its capacity is the manufacturer.

Our cooperation on supply and service & maintenance, CNC turning, vertical machining, robot feeding continues since 1999. Strong, competent and fast service is the most important factor for us to choose Tezmaksan

As Ditaş, we collaborated with different companies on robots and got good results. We saw that these difficulties of applications we face are more easily solvable with Cubebox from Tezmaksan.

Our industry uses robotic automation partially to reduce labor costs. In very high cost situations, we chose the Tezmaksan rental model to reduce the investment cost.

We are one of the first companies in the sector to use robots. Since we are the operator, the production with the robot is minimum. increased by 15 percent. Before connecting parts with robots and with vision measurement automation after machining faultless quality production and savings are ensured.

Dogan Spare PartsManufacturing and Technical Inc. was established in 1972 with the aim of producing tie rod end, ball joint, tie rod, swing arm, drawbar, stabilizer, vehicle infrastructure parts such as arm and V drawbar and after becoming operational in 1978 today, an annual production of 7 million 800 thousand units rod producing for Turkey’s largest OE with its capacity is the manufacturer.

Our cooperation on supply and service & maintenance, CNC turning, vertical machining, robot feeding continues since 1999. Strong, competent and fast service is the most important factor for us to choose Tezmaksan

As Ditaş, we collaborated with different companies on robots and got good results. We saw that these difficulties of applications we face are more easily solvable with Cubebox from Tezmaksan.

Our industry uses robotic automation partially to reduce labor costs. In very high cost situations, we chose the Tezmaksan rental model to reduce the investment cost.

We are one of the first companies in the sector to use robots. Since we are the operator, the production with the robot is minimum. increased by 15 percent. Before connecting parts with robots and with vision measurement automation after machining faultless quality production and savings are ensured.

17.08.2022

17.08.2022

Our References